A pneumatic diaphragm pump is a positive displacement pump driven by compressed air. With its unique structure and working principle, it is widely used in industrial fields and has many advantages. This article will analyze the advantages and attentions of pneumatic diaphragm pumps.

The advantages of pneumatic diaphragm pumps are mainly reflected in the following aspects:

1. Wide adaptability: Pneumatic diaphragm pumps are suitable for transporting various media, including liquids, colloids, particles, etc. Moreover, it can withstand high pressure and temperature and can adapt to the needs of various industrial environments.

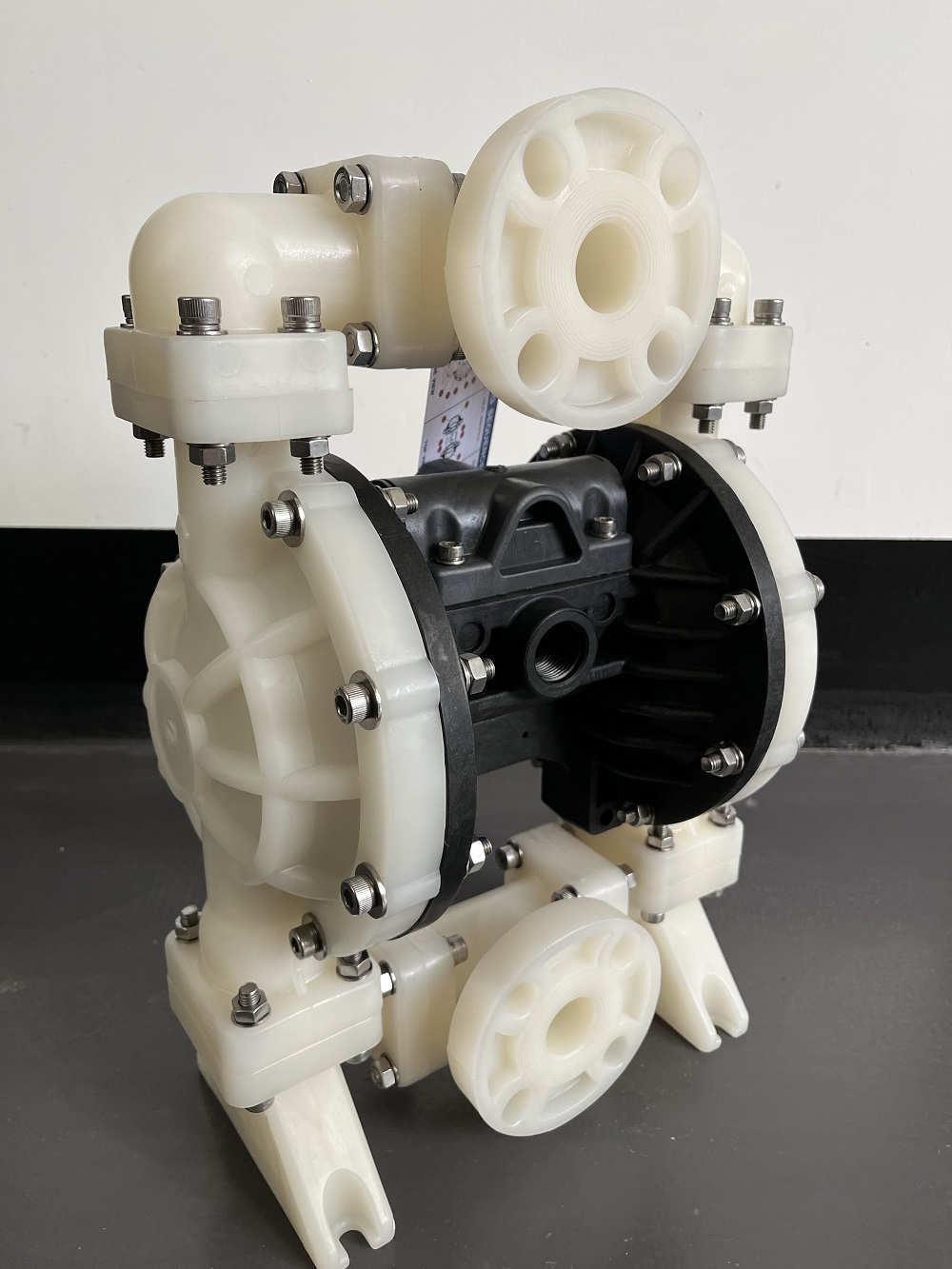

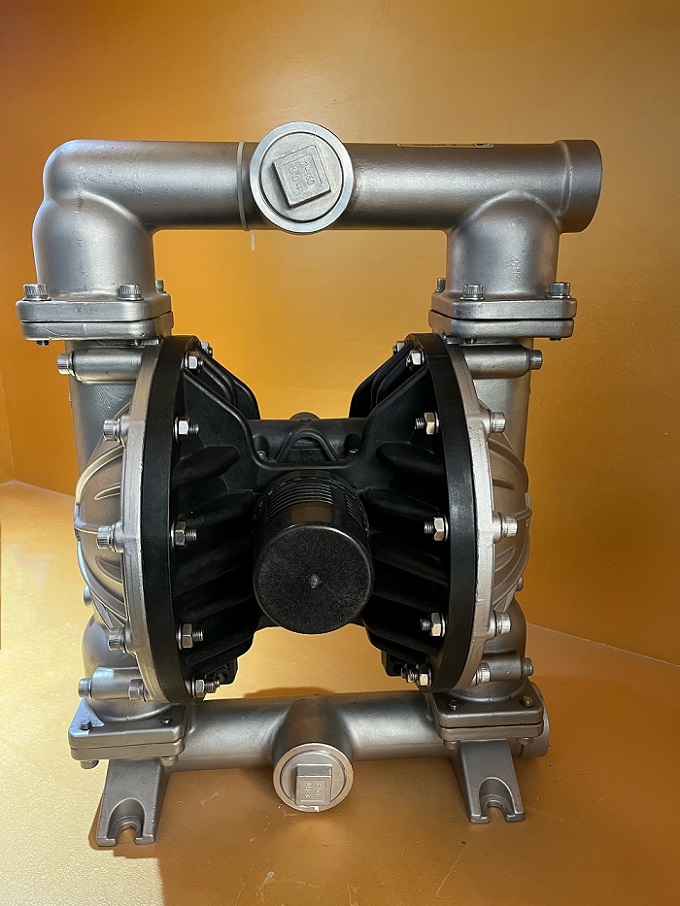

2. Strong corrosion resistance: The pump body and diaphragm of the pneumatic diaphragm pump are made of corrosion-resistant materials, such as stainless steel, PP, PVDF, etc. This enables the pneumatic diaphragm pump to exhibit better stability and long life in the delivery of corrosive media.

3. High reliability: The pneumatic diaphragm pump adopts pneumatic drive, which avoids problems such as unstable power supply and motor failure compared with electric pumps. At the same time, the pneumatic diaphragm pump has a self-priming function and can work normally without liquid supply, reducing manual intervention.

4.Simple maintenance: The structure of the pneumatic diaphragm pump is relatively simple and easy to maintain and clean. The diaphragm is the sealing material between the pump body and the air chamber, which isolates the working medium and compressed air, avoiding medium leakage and air pollution. When the diaphragm needs to be replaced, you only need to close the air source and medium supply valves and disassemble the diaphragm.

5. Low operating cost: The pneumatic diaphragm pump does not require additional power drive, saving energy consumption. Moreover, the throttling regulating valve of the pneumatic diaphragm pump can adjust the flow rate to achieve precise delivery control and reduce material loss and production costs.

When using a pneumatic diaphragm pump, we need to pay attention to the following points:

1. Select appropriate materials: Select appropriate pump body materials and diaphragm materials according to the properties of the working medium. Different media have different corrosiveness and viscosity, and materials need to be reasonably selected to ensure the stability and safety of the pump.

2. Air source pressure control: The work of the pneumatic diaphragm pump requires compressed air to provide power, so the pressure of the air source needs to be controlled. If the air source pressure is too low, the output flow rate of the pump will be insufficient, while if the air source pressure is too high, the pump body and diaphragm will be easily damaged.

3. Avoid overload operation: During the working process, avoid running the pneumatic diaphragm pump under high load for a long time. Overload operation will result in reduced pump performance, shortened service life, and may cause damage to the pump body and diaphragm.

4. Prevent air-liquid mixed discharge: In order to prevent air-liquid mixed discharge, appropriate valves should be installed at the inlet and outlet of the pneumatic diaphragm pump, and ensure that the inlet and outlet are tightly connected. This can reduce the direct contact between air and liquid and avoid problems caused by mixed air and liquid discharge.

5. Keep it clean and lubricated: Clean and maintain the pneumatic diaphragm pump regularly to keep the pump body and diaphragm clean. During use, appropriate lubricating oil can be used to lubricate the pump body and diaphragm to extend the service life of the pump.

Conclusion:

The pneumatic diaphragm pump has the advantages of wide adaptability, strong corrosion resistance, high reliability, simple maintenance, and low operating cost. However, during use, it is necessary to pay attention to material selection, control of air source pressure, avoid overload operation, prevent air and liquid mixed discharge, and maintain cleanliness and lubrication. Only by using and maintaining the pneumatic diaphragm pump properly can give full play to its advantages and improve production efficiency and work safety.

DEFU produce air diaphragm pump more than 10years, DEFU AOK series pump has the same performance with the graco diaphragm pump, with high quality, if you interested in 1 inch diaphragm pump, 2inch diaphragm pump and 3 inch diaphragm pump, pls contact sales9@defupump.com directly, DEFU will give you reply in short time. And will give you professional solution according to your media.