Air double diaphragm pump is a pump that uses a special diaphragm to separate liquids from moving parts. It can transport various types of liquids by changing its volume. The working principle of the diaphragm pump is mainly based on the reciprocating movement of the diaphragm. This movement is achieved by pneumatic movement, which in turn causes the diaphragm to move to the inside or outside of the pump chamber, thereby changing the volume in the pump chamber and achieving suction and discharge actions.

Air Diaphragm pump in food factory is a commonly used conveying equipment, its function is to convey liquid from one place to another. It uses a diaphragm structure to drive the flow of liquid through the action of compressed air. Air Diaphragm pumps in food factories are widely used in the food industry, and their uses mainly include the following aspects:

1. Conveying food raw materials: Diaphragm pumps in food factories can be used to transport various food raw materials, such as juices, sauces, condiments, etc. Due to the structural characteristics of the diaphragm pump, it can effectively maintain the purity and hygiene of raw materials and avoid contamination and cross-infection.

2. Transporting food additives: Diaphragm pumps in food factories can be used to transport various food additives, such as pigments, flavors, preservatives, etc. Due to the structural characteristics of the diaphragm pump, it can ensure accurate metering and even distribution of additives, improving product quality and taste.

3.Transporting food wastewater: Food factory diaphragm pumps can be used to transport food wastewater, such as washing water, sewage, etc. Due to the structural characteristics of the diaphragm pump, it can effectively treat wastewater, reduce environmental pollution, and meet environmental protection requirements.

4. Transporting food by-products: Diaphragm pumps in food factories can be used to transport food by-products, such as dregs, slurry, etc. Due to the structural characteristics of the diaphragm pump, it can effectively handle by-products, improve resource utilization, and reduce production costs.

5. Conveying food liquids: Food factory diaphragm pumps can be used to convey various food liquids, such as milk, yogurt, jam, etc. Due to the structural characteristics of the diaphragm pump, it can ensure smooth flow of liquid, avoid oxidation and deterioration, and maintain the freshness and taste of the product.

Conclusion:

In short, food factory diaphragm pumps play an important role in the food industry, which can effectively improve production efficiency and product quality, and ensure food safety and hygiene. At the same time, the structural characteristics of the diaphragm pump also make it highly adaptable and flexible, and can meet various needs in different food production processes.

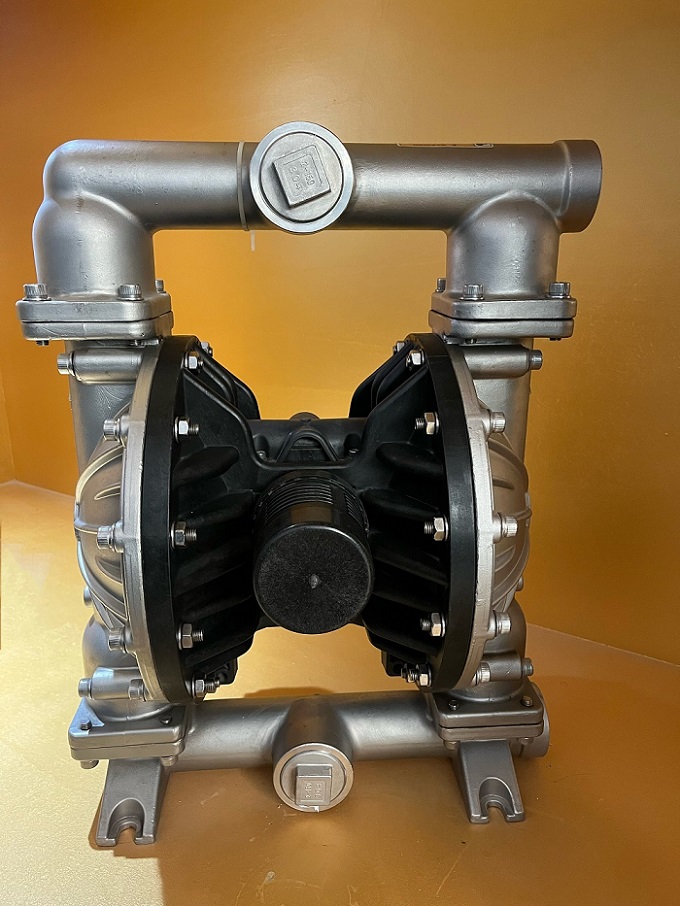

DEFU produce air diaphragm pump more than 10years, DEFU AOK series pump has the same performance with the graco diaphragm pump, with high quality, if you interested in plastic pneumatic diaphragm pump, stainless steel diaphragm pump and Aluminum diaphragm pump, food grade diaphragm pump pls contact sales9@defupump.com directly, we have different specification with large flow rate. And DEFU will give you reply in short time. And will give you professional solution according to your media.