AODD pumps can be easily moved and require only a source of compressed air to operate. Some users choose to cart-mount pumps, allowing for even easier mobility and application versatility. A single AODD pump can be easily used for different jobs around the plant. AODD pumps do not have to be permanently affixed to a single location and do not require an electric power source. With suction/discharge hoses and an air line, you can simply place the pump on the floor and get to work. Some plants even use AODD pumps in a pinch to temporarily replace other pumping technologies while they are being repaired, as they can take much longer than AODD units to repair when taken out of service. But how do I know what type of air diaphragm pump to buy?

Here are the some important considerations for choosing an AODD(Pneumatic diaphragm pump).

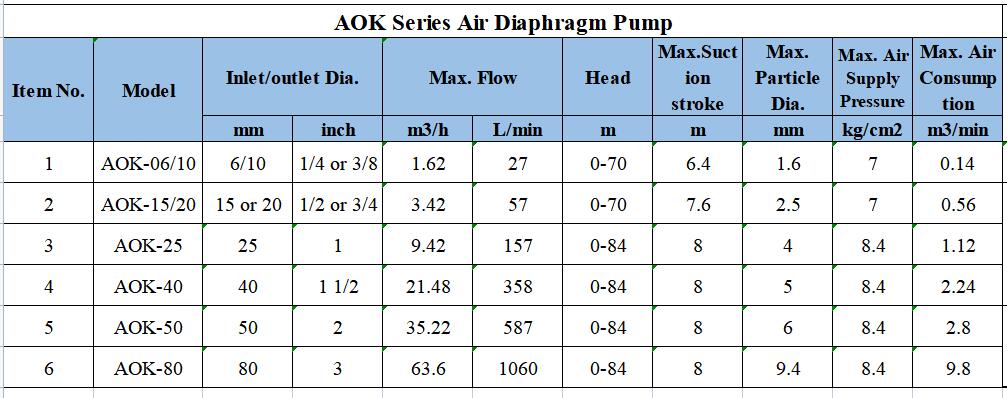

1.Flow rate and pressure(head): In order to select the appropriate double diaphragm pump, it’s important to understand the required flow rate and pressure in order to achieve maximum AODD pump efficiency. Diaphragm pump flow rate is the volume of fluid you can transport within a given time. The Diaphragm pump’s pressure is intertwined with the flow rate, Please refer to the diaphragm pump manufacturer’s performance curve,its help determine the relationship between flow and pressure. From market, the AODD pumps can produce pressures up to 8.4 bar and flow rate up to 280 gpm (1,060 lpm), Below are the pump size, pressure and flow rate for your reference. If you desire a higher flow rate, you’ll need a larger pump with larger port sizes. The higher the flow rate, the faster your job gets done.

If you desire a higher flow rate, you’ll need a larger pump with larger port sizes. The higher the flow rate, the faster your job gets done.

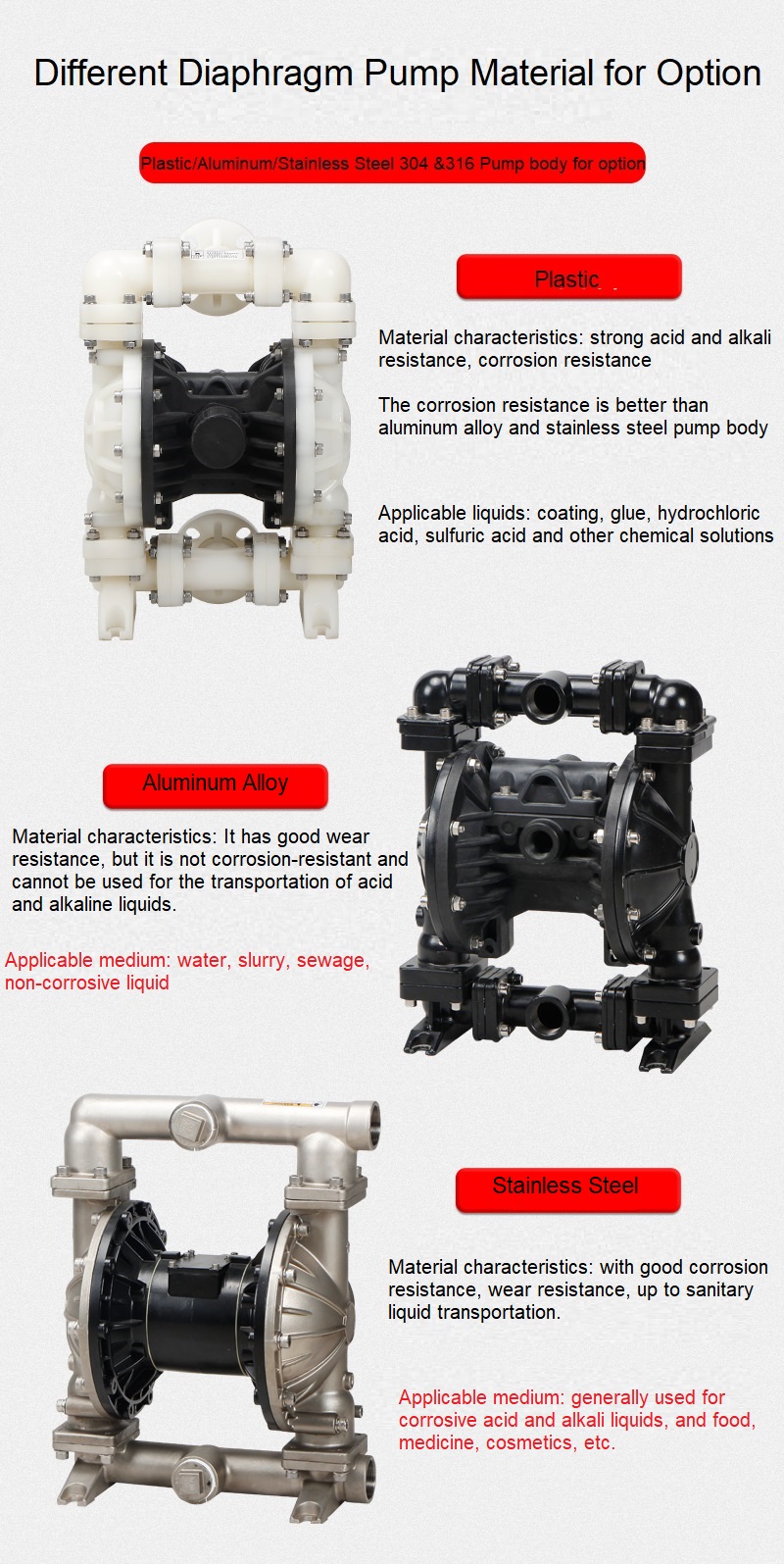

2. Liquid-the liquid determine the pump body, diaphragm,ball and ball seat’s material. Pump body material are: Aluminum alloy, Cast Iron, Plastic(plastic polypropylene),stainless steel (304/316). Diaphragm material are: Teflon,Santoprene,Hytrel, Viton, Buna-N.

PTFE Material used for balls & diaphragms:Excellent when used with solvents,Poor abrasion resistance,Widest chemical compatibility with fluids

Santoprene Material used for seats, balls & diaphragms:Good abrasion and chemical resistance,Not for use with solvents or hydrocarbons,Often substituted for EPDM or EPR .

Buna-N Material used for seats, balls and diaphragms:Good for petroleum-based fluids,Not for use with strong solvents or chemicals

polypropylene units are widely used for chemical liquid. because of its excellent chemical resistance, flex life, abrasion resistance and low cost.

Stainless steel units are a great choice because they work well in outside conditions and can handle direct sunlight better than plastic pumps (plastic can be affected by UV radiation). Stainless steel also deals with extreme cold and hot temperatures better than plastic units.

So according to the transfer liquid and application to select pump material.

3. Viscosity – The viscosity of your process fluid is also important. Pneumatic diaphragm pump can transfer viscous materials below 10,000 cps, but when transferring more viscous materials, you should choose a diaphragm pump with a flow rate one size larger than the required flow rate, because the flow rate data of pneumatic diaphragm pumps are all tested with clean water. It is calculated that the greater resistance of viscous materials will reduce the flow rate.

4. Temperature – Your choice of pump necessarily need to depend on the temperature of the liquid being pumped.