Air-operated double diaphragm pumps(AODD) are used to transfer liquid in mining, coating,Chemical, oil, water/waste water treatment and some other industrial. They are relatively low cost and reliable. And they can be run dry.

This article will cover how to operate diaphragm pump correct.

1. Installation and Start-up

Locate the pump as close to the product being pumped as possible. Keep the suction line length and number of fitting to a minimum. Don’t reduce the suction line diameter.

For installations of rigid piping, short sections of flexible hose should be installed between the pump and piping. The flexible hose reduces vibration and strain to thee pumping system.

2. Air Supply

Air supply pressure cannot exceed 125psi(8.6bar). Connect the pump air inlet to an air supply of sufficient capacity and pressure required for desired performance. When the air supply line is solid piping, use a short length of flexible hose between the pump and the piping to reduce strain to the piping. The weight of the air supply line, regulators and filters must be support by some means other than the air inlet cap. Failure to provide support for the piping may result in damage to the pump. A pressure regulating valve should be installed to insure air supply pressure does not exceed recommended limits.

3. Air Inlet and Priming

To start the pump, open the air valve approximately 1/2” to 3/4” turn. After the pump primes, the air valve can be opened to increase air flow as desired. If opening the valve increases cycling rate, but dose not increase the rate of flow, cavitation has occurred. The valve should be closed slightly to obtain the most efficient air flow to pump flow ratio.

4. Between uses

When the pump is used for materials that tend to settle out or solidify when not in motion, the pump should be flushed after each use to prevent damage(product remaining in the pump between uses could dry out or settle out. This could cause problems with the diaphragms and check valves at restart) in freezing temperatures the pump must be completely drained between uses in all cases.

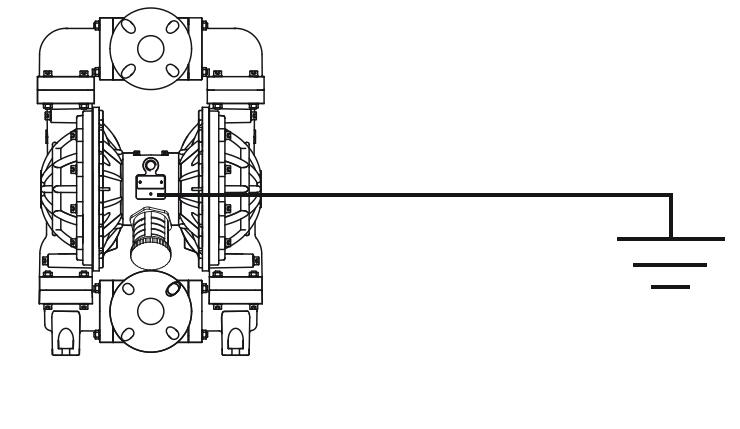

5. Grounding the pump

To reduce the risk of static electrical sparking, the pneumatic diaphragm pump must be grounded. Check the local electrical code for detailed grounding instruction and the type of equipment required.

If you have any problems during using AODD pump, pls feel free to contact with Ms Cindy (sales9@defupump.com). we will give you support shortly.