The double diaphragm pump is a versatile workhorse that enables users across a hugely diverse range of industries to standardies on a single pump type that for handling a wide variety of fluids. So long as there is a compressed air supply available the pump can be installed wherever it is required and should circumstances change it can be moved round a plant and switched to other operations with ease. Whether to fluid be handled requires a gentle pumping action, is chemically or physically aggressive the positive displacement AODD pump offers an efficient and low maintenance solution.

This article will show how to install Pneumatic Diaphragm Pump.

Tightening Threaded Fasteners Before First Use

Before using the pump for the first time, check and retorque all external fasteners. After the first day of operation, retorque the fasteners. Although pump use varies, a general guide-line is to retorque fasteners every two months.

Installation/Mountings

l These pumps can be used in a variety of installations. Be sure the mounting surface can support the weight of the pump, hoses and accessories, as well as the stress caused during operation.

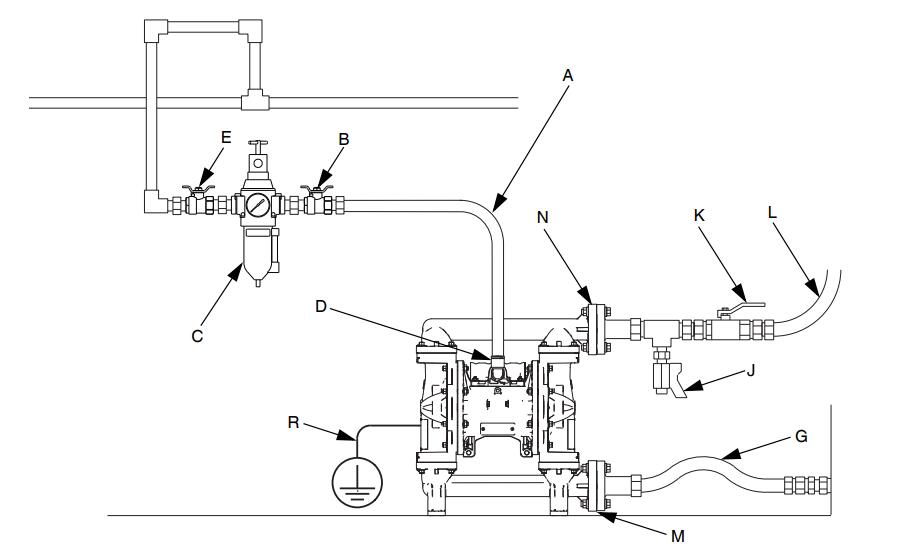

l Below is one of our installation example. On the installation, mount the pump using screws and nuts.

A Air supply line B Bleed-type master air valve (required for pump)

C Air filter/regulator assembly D Air inlet

E Master air valve (for accessories) G Grounded, flexible fluid supply line

J Fluid drain valve (required) K Fluid shutoff valve

L Grounded, flexible fluid outlet line M Fluid inlet

N Fluid outlet

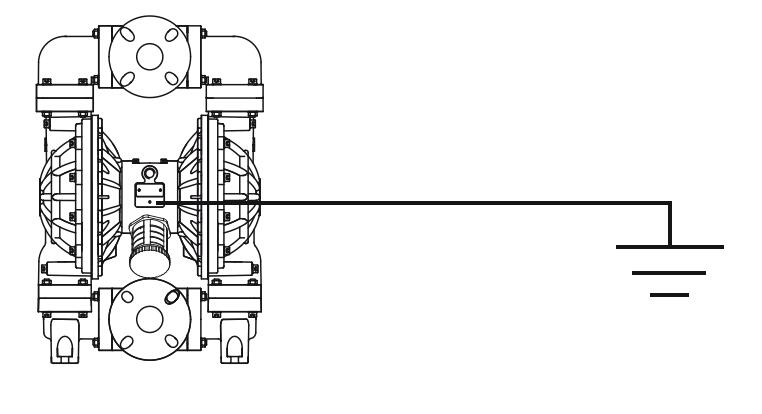

R Ground wire (required for aluminum, conductive polypropylene, and stainless steel pumps; Below is

the picture for reference)

l Grounding the pump

To reduce the risk of static electrical sparking, the pneumatic diaphragm pump must be grounded. Check the local electrical code for detailed grounding instruction and the type of equipment required.

l Prolonged exposure to UV radiation will degrade natural polypropylene components of the pumps. To prevent potential injury or equipment damage, do not expose pump or the plastic components to direct sunlight for prolonged periods.

If you have any problems during using diaphragm water pump, pls feel free to contact with Ms Cindy (sales9@defupump.com). we will give you support shortly.